Hard sealed ball valve Q41H-16C

Fax:0576-82230069

Email:179386676@qq.com

2020

05/25 10:16:27

Opening and closing indication of floating ball valve

The ball, valve stem, and handle are the moving parts of the valve and are an assembly unit. The valve stem head adopts a flat square structure, which can easily distinguish whether the valve is in the open or closed position from the position of the handle. When the handle or valve stem is parallel to the pipeline axis, the valve is in the open position; When the handle or valve stem is perpendicular to the pipeline axis, the valve is in the closed position.

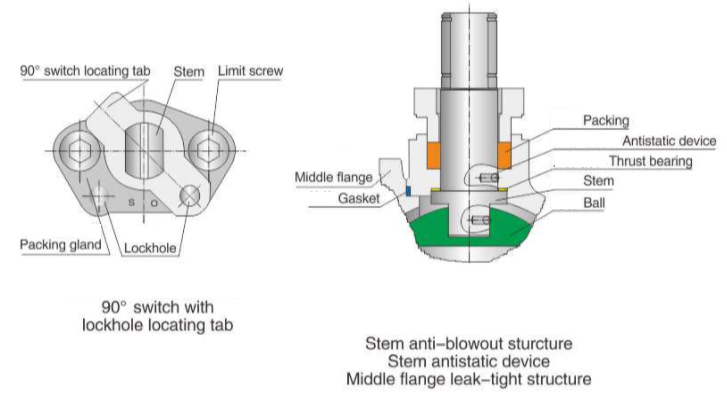

Valve locking position

To prevent accidental operation of the valve, a lock can be used to lock the valve in its fully open and fully closed positions, especially for valves installed in the field or when the process flow does not allow opening or closing the valve. To prevent other personnel from operating the valve incorrectly, it is important to lock the valve position. Therefore, adding locking hole positioning plates during valve design according to user needs can meet their process requirements.

Middle flange without external leakage structure

The connection between the valve body and the left body is sealed with a gasket. In order to prevent sealing leakage caused by fire, high temperature, or vibration, the valve body is specially designed to be in contact with the left body metal to form a stop flange, ensuring no external leakage.

Valve stem anti flying structure

When the medium passes through the valve, the pressure in the cavity of the valve body may push the valve stem out (or during valve maintenance, if there is pressure in the cavity, the valve stem and medium may fly out when disassembling the valve, causing injury to personnel). To prevent this situation from occurring, a protruding structure is installed below the valve stem. In this way, even if the packing, thrust bearings are burned or damaged due to other reasons during a fire, the pressure of the medium inside the valve body will cause the valve stem protrusion to come into close contact with the sealing surface on the valve body, preventing a large amount of medium from leaking from the damaged packing area.

Fireproof structure

When a fire occurs, non-metallic (non fireproof materials) such as packing and valve seats will be burned out, and a large amount of leaked media may further promote the spread and expansion of the fire. At this time, the fireproof structure of the valve can block a large amount of media leakage. As shown in the figure, once the valve seat is burned, the sphere will directly contact the metal surface on the valve body, thereby preventing a large amount of medium from leaking from the burnt valve seat.

400 Phone:400-6060-168

Phone:0576-82230067 82230068

Mobile:17816581618